Disruptions continue to impact freight movement. Planning for unforeseen circumstances can help to keep goods moving through supply chain bottlenecks.

Ask partners these questions to uncover creative solutions before shipments leave the dock.

1. Can more providers and/or carriers be added to your supply chain?

A single transportation option severely limits supply chain shipping options. Space availability is king. Require suppliers to work with companies that have options. Ask these questions:

-

- Can a different forwarder be selected?

- Can exit/entry ports be chosen?

- Can the shipment be packed via skids? (see question 4 below)

2. Can more entry and/or exit ports be selected?

Require suppliers to add port options. It may increase initial cost, but add a long-term advantage to keep shipments moving.

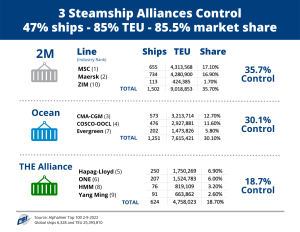

3. Will shipments be diversified among Alliances?

Three global steamship Alliances control nearly 85% of the market. The structure gives carriers control of pricing by sharing the cost of pulling (blanking) vessels out of service within the alliance to match capacity with container demand. Diversified shipments mean fewer overall bottlenecks.

4. Can products for shipping be shipped using skids instead of being floor loaded?

How a shipment is loaded can increase overall shipping cost. Require the supplier to palletize goods with quality heat treated skids. The added cost at point of origin can lower labor and storage, demurrage, and/or chassis charges upon arrival to North America.

5. What ports do suppliers use for U.S. imports?

Infrastructure at ports is critical to shipment movement inland. There are 23 ports available to steamships entering North America. Just 10 accommodate ships carrying 16,000 TEU or more and have infrastructure to move shipments inland by truck or rail. See options.

6. How will product move from the ports to the destination?

Chicago has more than 50 freight rail yards. Rail yards are available in less congested cities including: Indianapolis, Indiana; Cincinnati, Cleveland, Columbus and North Baltimore Ohio; Louisville, Kentucky; Detroit, Michigan; and St Louis, Missouri. Diversifying incoming inventory through more than one rail ramp can shorten travel time. See options.

7. Do your goods need to ship through the West Coast?

If not, consider routing through the Panama Canal with arrival through an East Coast port.

8. What communications can be expected during transit? Hear our philosophy in this video.